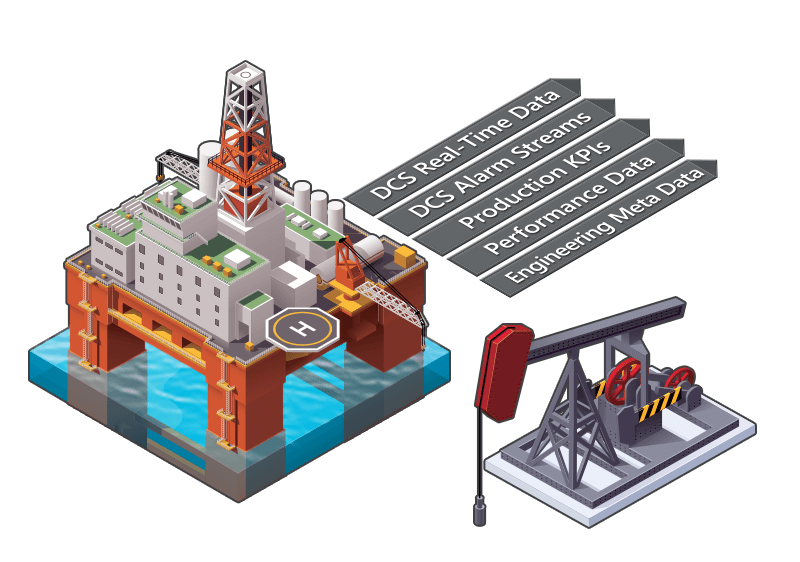

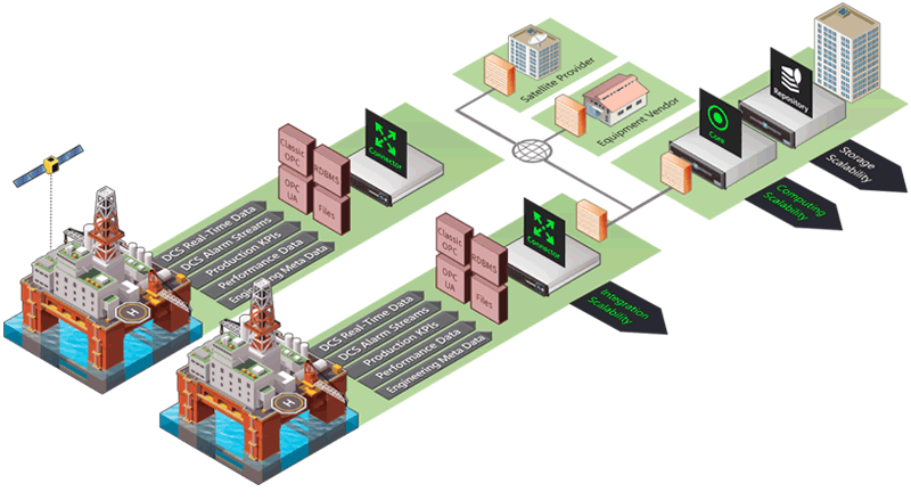

Oil and gas Industries usually operate a large number of exploration and production sites, preferably in harsh environments and/or very far locations. Depending of the size and production stage, different control scenarios may exist – from smaller, low-staffed sites to well-equipped DCS-controlled environments. Independent of local control, it is desirable to consolidate process data of all types and production stages centrally, and also manage third-party real-time data access from a central location.

Central Repository

All data of system:Nozom, including data from the field, but also internal system monitoring, statistics and logs, is stored in the central repository, which serves also as the unique configuration interface of the entire system. To be completely independent from the individual data source and flexible to reflect any given structures, a schema-free open database is used. system:Nozom consolidates all data into one central repository, that can be easily accessed by any modern corporate IT.

Core & Computing Scalability

system:Nozom´s Core Service controls the underlying architecture of Connector instances. It distributes configurational changes, processes incoming data and creates reflective images of the data in the Repository, such as the Process Image or Data History. To allow for very large systems or redundancy, system:Nozom supports multiple, parallel Core Service instances. You operate dozens of large platforms? No problem.

Equipment Vendor

It is very common that specialized suppliers like drilling equipment manufacturers want their own data access, while sharing the network infrastructure with the operating company, or multiple operators want to share the production data. system:inmation allows to create virtual address spaces, giving any party exactly that kind of access it requires and which is granted. Centrally controlled.

Satellite Provider

With satellite providers or other communication means such as point-to-point radio or cellular radio you cannot expect the bandwidth comparable to fiber networks. system:Nozom’s protocol is prioritized and uses available bandwidth always first for real-time data, scheduling other data transfers such as file transfers into the remaining slots.

Network Security

Especially with remote locations where your process data crosses the domains of external communication suppliers, you may want more data security than just the VPN. Whilst using only a single TCP port for all kinds of system communication, system:Nozom uses its own SPROX protocol, which is compressed and encrypted and has no backdoor for anyone

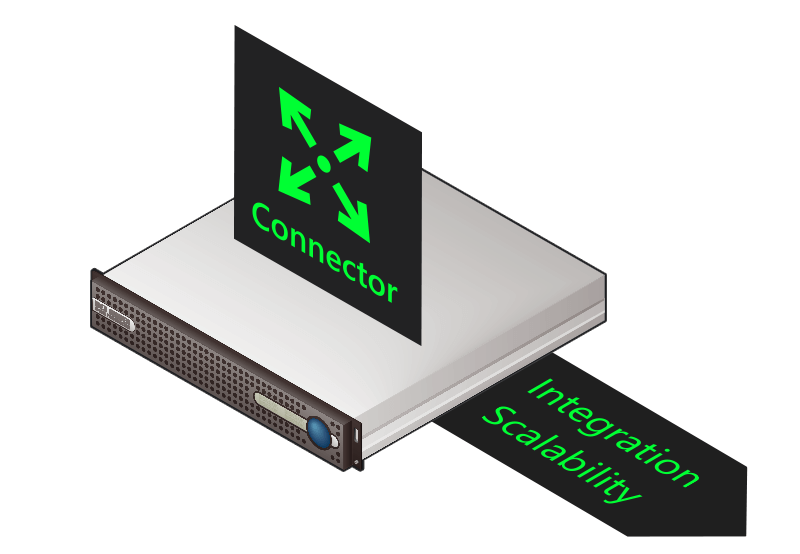

Connector & Endpoint System Integration Scalability

The system:Nozom Connector is the service which resides at the remote location and forwards all data to the central hub. Depending on the scale of the architecture and data sources to be integrated, it can be one or many Connectors per site. Integrating a new site to the enterprise system is only a matter of adding more Connectors to the overall architecture. Zero-engineering required.

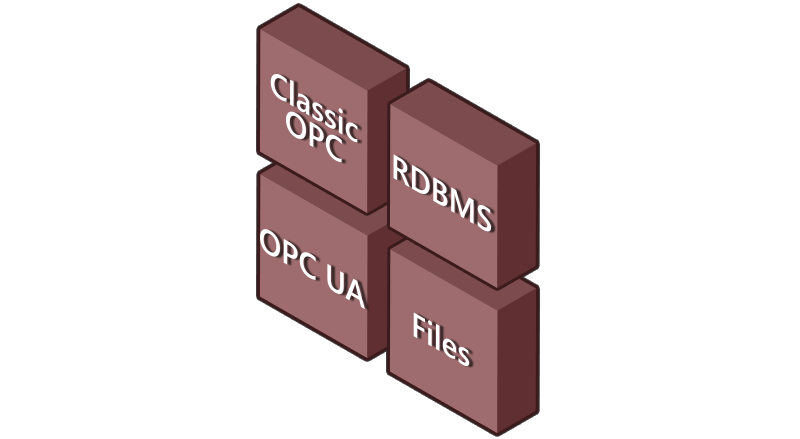

Interface Standards

Data does not only originate from different systems, but is also exposed in different formats depending on the interface being used. system:Nozom supports all industry standards for data acquisition, from ‘classical’ COM-based OPC to OPC UA, as well as other traditional formats like text files or OLEDB/ODBC, which allows to get data from almost any source used within the control/performance layer of the plants.

Support for Various Information Sources

Oil and Gas sites may or may not have a fully integrated DCS which allows access to any kind of surface or sub-surface data. system:Nozom’s Connector component allows to bundle any number of OPC and non-OPC data sources together, redundant or not with zero engineering effort on site.